How Robotic Cleaning Mechanisms Work: Inside IFBOT X3 & M20

Solar panel cleaning robots are now a critical part of solar operations — from residential rooftops to utility-scale farms. But many operators still ask the same question:

How do these robots actually work?

Behind every smooth cleaning pass is a combination of smart design, mechanical engineering, sensors, and cleaning technology shaped by real-world field conditions. In this article, we break down the core mechanisms inside IFBOT’s X3 dry-cleaning robot and M20 wet-cleaning robot, showing how each system removes dirt while protecting panel surface integrity.

This is your deep, plain-language guide to the technology that keeps solar producing at peak efficiency.

1. Why Robotic Cleaning Mechanisms Matter

Solar panels lose power when they’re covered with dust, sand, bird droppings, or sticky industrial residue. Depending on the environment, energy loss can range from 5% to 35% — and even more in arid or polluted regions. Robots help reduce that loss consistently and safely.

And the mechanism matters.

The way a robot cleans — dry vs wet, brush vs roller, water vs suction — directly affects:

cleaning efficiency

output recovery

panel safety

water usage

maintenance frequency

operational cost

That’s why IFBOT built two different systems: X3 for dry dust and M20 for heavy or sticky dirt.

2. Inside the IFBOT X3: Ultra-Light Dry Cleaning Mechanism

The IFBOT X3 is designed for rooftops, sloped arrays, and water-scarce regions where dust builds up quickly. Its cleaning mechanism combines nano-fiber rollers, vacuum suction, and lightweight engineering to safely remove dry contaminants.

2.1 Nano-Fiber Brush Roller

The core cleaning element is a soft nano-fiber roller engineered to lift dust without scratching the panel. Nano-fiber technology creates thousands of micro-contact points, allowing the roller to:

capture fine dust

lift loose sand

remove surface particles

protect anti-reflective (AR) coatings

Its material is gentle and pressure-balanced, ensuring long-term panel health.

2.2 Vacuum Suction Assist

As the roller lifts dust, IFBOT integrates a low-pressure vacuum suction channel that immediately collects loose debris. This prevents:

dust recirculation

residue dragging

streaking or re-settling

Vacuum assist is especially important on rooftops where wind can blow debris back.

2.3 Ultra-Lightweight Chassis

At only 6.2 kg, X3 is up to 80% lighter than conventional robots. The lightweight body reduces downward pressure on the panels, which is vital for:

safety on framed and frameless modules

reducing micro-abrasion risk

improving mobility on steep slopes (up to 50°)

2.4 Dual Hot-Swappable Batteries

Continuous cleaning needs continuous power. IFBOT designed dual hot-swappable battery slots, allowing the operator to replace batteries without stopping the robot.

2.5 Autonomous Navigation

Sensors and algorithms help X3:

map panel boundaries

detect edges

maintain straight paths

optimize overlap between passes

This ensures even cleaning and efficient coverage in tight rooftop layouts.

3. Inside the IFBOT M20: High-Power Wet Cleaning Mechanism

The M20 is built for environments where dirt is not just dust — coastal areas, bird activity zones, industrial fallout, and solar farms with sticky or caked residue. Its cleaning mechanism uses dual brushes, high-pressure spray, and water recycling to perform heavy-duty cleaning safely.

3.1 Dual-Brush System (Rubber + Bristle)

M20 uses a hybrid dual-brush design:

Rubber brush breaks surface adhesion

Bristle brush scrubs away dissolved residue

This two-stage action removes dirt that dry cleaning cannot, including:

bird droppings

pollen clumps

salt crust

industrial pollution film

The brush length (1300 mm) also gives 99% edge coverage, reducing manual touch-ups.

3.2 High-Pressure Water Spray

A built-in spray bar distributes water precisely in front of the brushes. This helps soften, dissolve, and lift stubborn contaminants without flooding the panel.

The controlled flow prevents:

unnecessary water waste

run-off issues on sloped panels

streaking

3.3 Dynamic Mud-Water Separation

This is one of M20’s biggest advantages: real water recycling.

The robot channels dirty water through a small mud-water separation module so it can reuse part of the water, reducing overall consumption. This improves sustainability and makes the unit more efficient in large installations.

3.4 Cruise Control Motion

To prevent brush-pattern streaks or uneven cleaning, the M20 uses cruise-control algorithms to maintain stable:

pressure

speed

brush-panel contact

This ensures consistent results across large fields or seasonal dirt buildup.

3.5 Safety Mechanisms

Because wet robots handle more complex environments, IFBOT added:

triple fall protection

edge detection

anti-slip traction

stall protection

This is especially important on industrial rooftops and large PV farms.

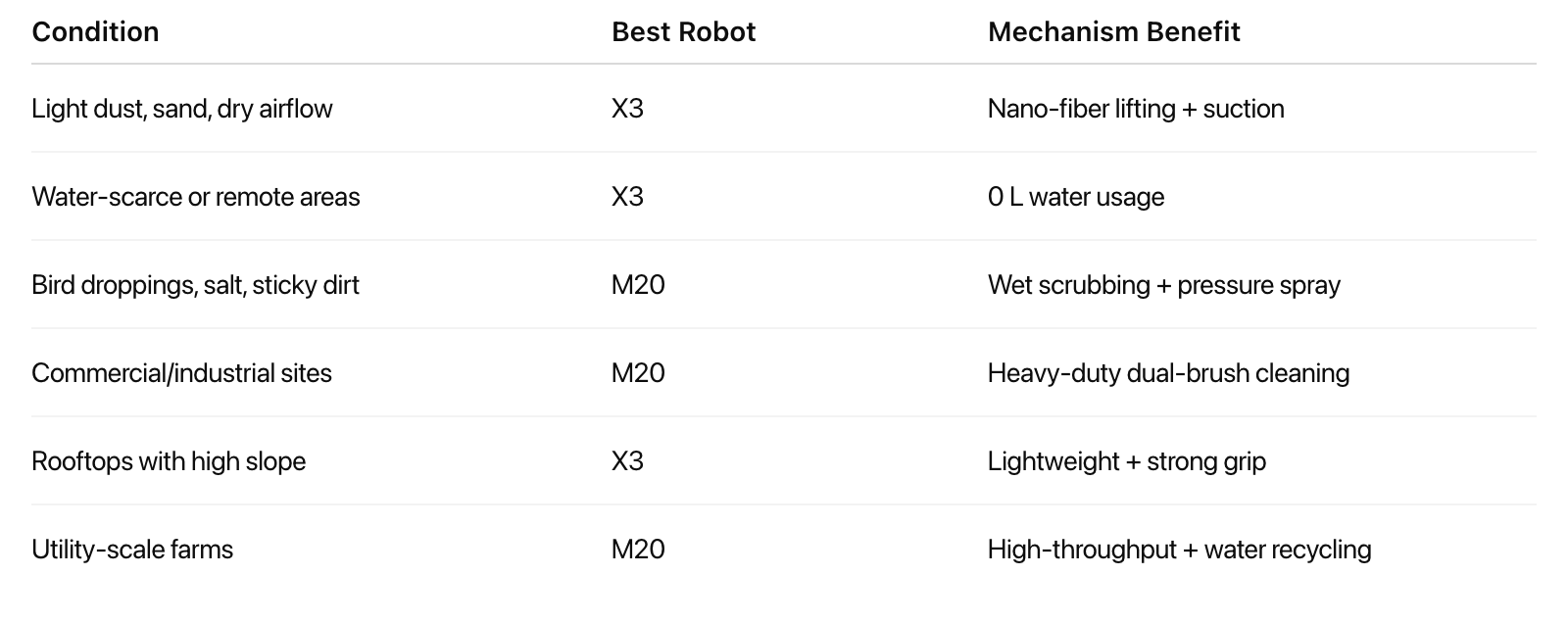

4. Dry vs Wet Cleaning Mechanisms: When Each One Works Best

Both robots solve different problems — that’s why IFBOT built specialized mechanisms rather than a “one mode fits all” system.

5. How IFBOT Designs for Real Conditions

Every cleaning mechanism in IFBOT’s lineup is shaped by field testing:

windy factory rooftops

dusty inland solar parks

coastal arrays with salt buildup

agricultural and fishery solar sites

cold or low-pressure zones

steep, uneven terrain

Real sites are unpredictable.

Mechanisms must adapt — not the other way around.

6. Final Takeaway

The cleaning mechanism is the heart of any solar panel robot. Whether it’s the X3’s ultra-light dry-cleaning rollers or the M20’s dual-brush wet-cleaning system, IFBOT designs each tool to match specific on-site challenges.

Choosing the right robot starts with understanding the dirt, not the device.

If you’d like help determining the best cleaning strategy for your site, the IFBOT team can assess your environment and recommend the right combination of tools.